Technical and design co-engineering

Thanks to a highly specialized technical team with many years of experience, Lampa Plastic is able to produce plastic materials, of various types and for different application sectors.

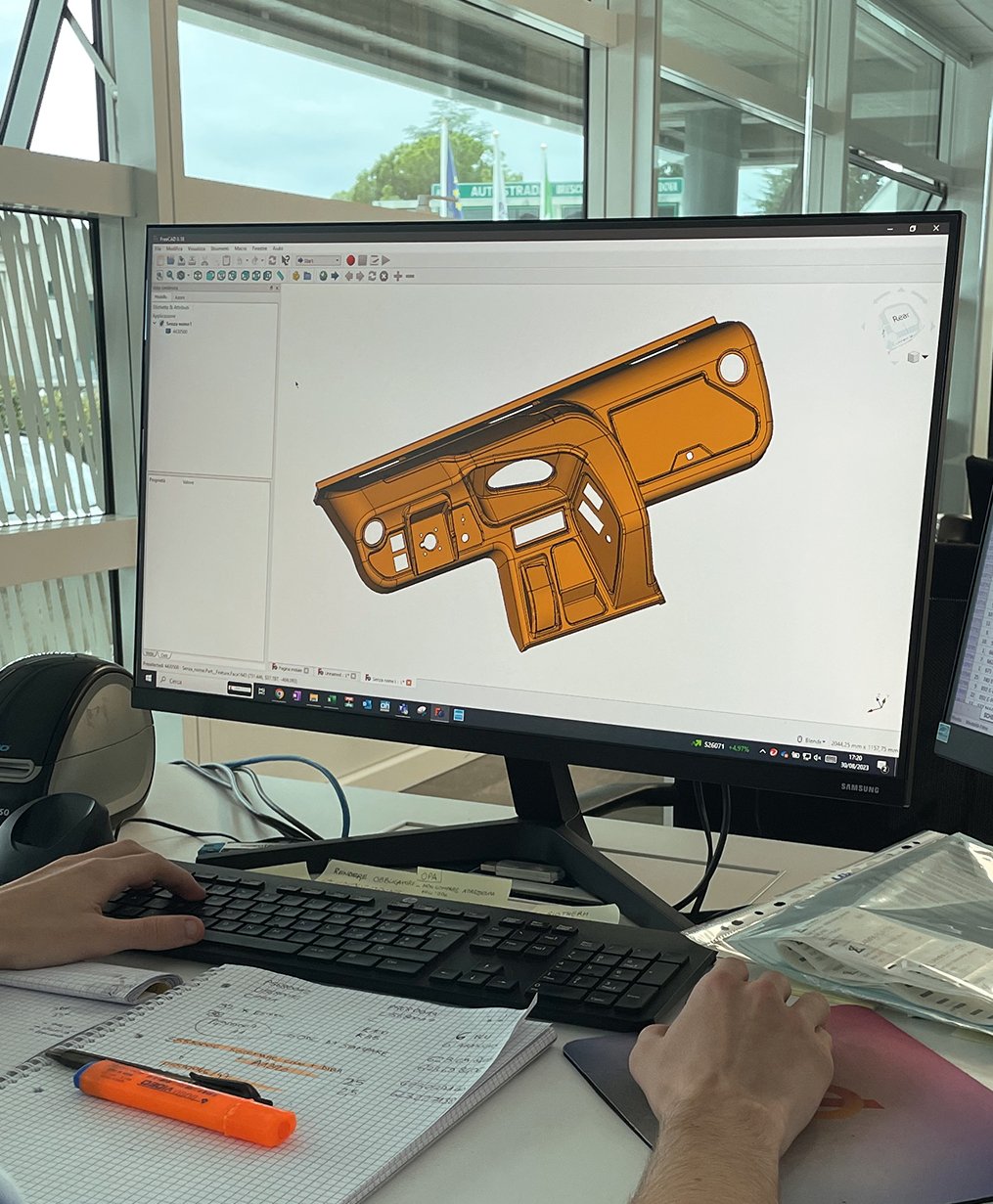

The use of the latest generation software and hardware allows us to design and offer high quality solutions at sustainable costs.

We follow the customer in every step of the production cycle: from the initial assessment with the design of the mold, to the choice of material, up to the aesthetic result of the finished product.

We study the best technical and construction solutions and provide consultancy, product engineering and bodywork design services to fully satisfy the needs of our customers.

Our certificates

Organization

Since 2017, Lampa Plastic has embarked on an important renovation with a new business project, through the modernization of facilities, introduction of new machines and highly qualified employees.

.01 Consultancy

Design

Offices: after a major renovation, the administration and commercial areas are located on the top floor, while the production, technical and quality assurance offices are on the ground floor.

.03 Assembly,

Injection of

polyurethane resins

Foaming department + assembly line with robotic arm.

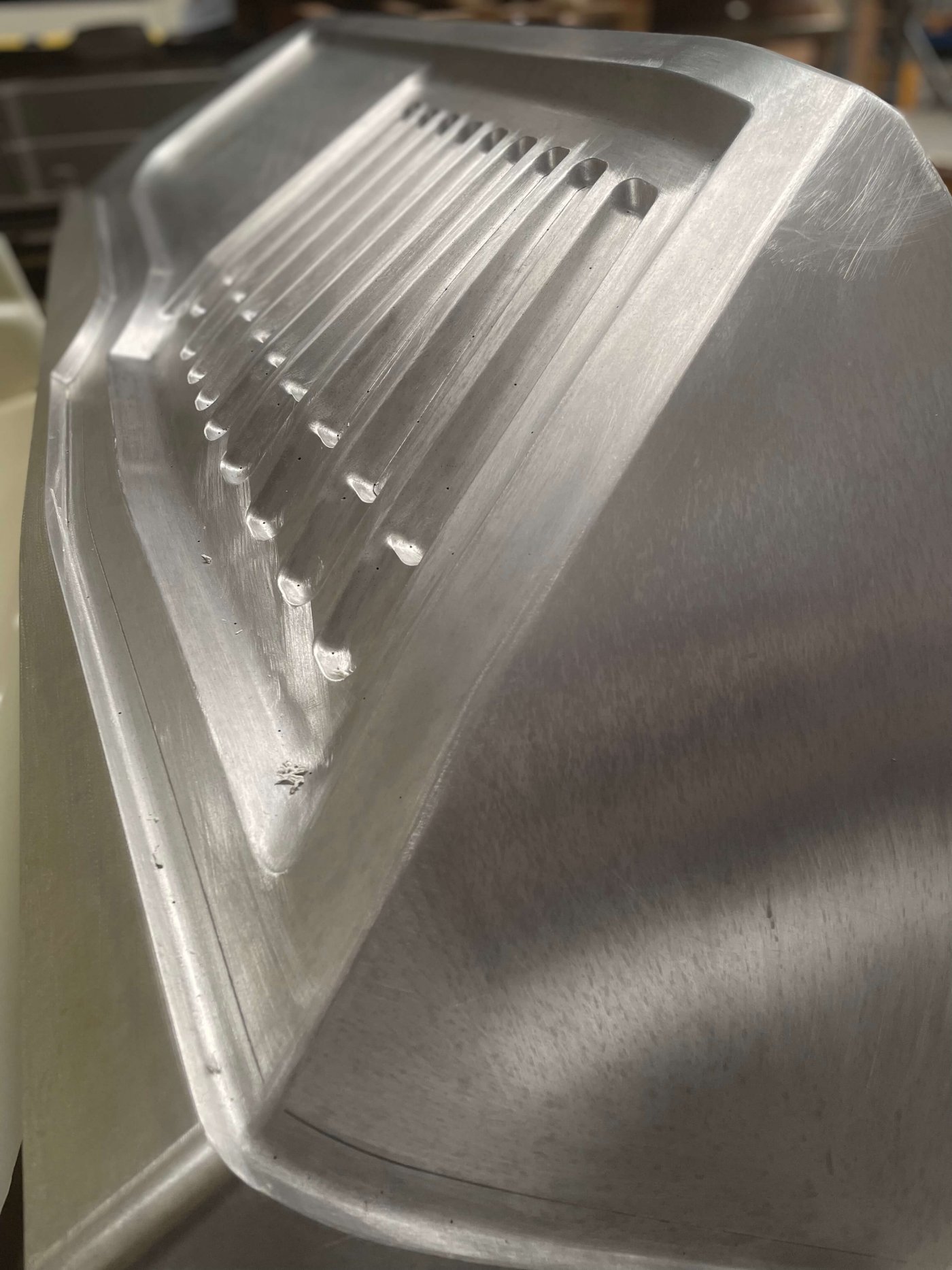

.04 Cutting

and trimming

This department displays 5 CNC robots with 5 axes featuring most recent technological outfits.