Assembly of Plastic Materials

and Injection of Polyurethane Resins

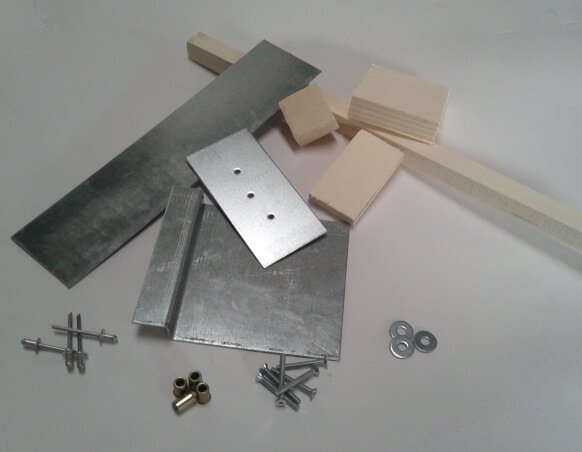

Lampa Plastic features an entire department specialized in glutting/installing parts (rivets, threaded inserts, brackets, gaskets, filters, etc.) and ultrasonic welding.

During the mold design phase, all couplings with different materials are studied. This allows us providing the customer with the finished piece, optimizing processes and reducing production costs.

We also have 3 foaming stations for the injection of polyurethane foam resins, to satisfy any need for soundproofing, thermal insulation and structural reinforcement.

Thanks to its excellent thermal and acoustic performance, polyurethane foam is suitable for several uses: such as, for example, in refrigeration, to keep the temperature controlled; in construction, for acoustic and/or thermal insulation panels or to improve structural integrity (when there is a need to insert accessories).

We also perform laboratory tests upon request.

Organization

Since 2017, Lampa Plastic has embarked on an important renovation with a new business project, through the modernization of facilities, introduction of new machines and highly qualified employees.

.01 Consultancy

Design

Offices: after a major renovation, the administration and commercial areas are located on the top floor, while the production, technical and quality assurance offices are on the ground floor.

.03 Assembly,

Injection of

polyurethane resins

Foaming department + assembly line with robotic arm.

.04 Cutting

and trimming

This department displays 5 CNC robots with 5 axes featuring most recent technological outfits.